For years, the 3D design world has operated with a key limitation: geometry defines the shape, while textures are added later as an afterthought. This method works well for many purposes, but it often leads to problems when it comes to 3D printing, manufacturing, and high-fidelity outputs. Traditional workflows often fail to meet the stringent demands of production environments, leaving professionals with hours of manual cleanup.

The Challenge with Traditional 3D Texturing in Printing Workflows

The core issue lies in the conventional workflow of “build the mesh first, then project textures onto it.” While this is effective for digital renders, it becomes problematic when creating models for real-world applications. Issues such as stretched textures, misaligned seams, and occluded details become more apparent when the model needs to be 3D printed or manufactured.

As the 3D design community continues to evolve, Hitem3D 2.0 steps in to provide a robust solution for these challenges, specifically targeting high-quality 3D printing and manufacturing use cases.

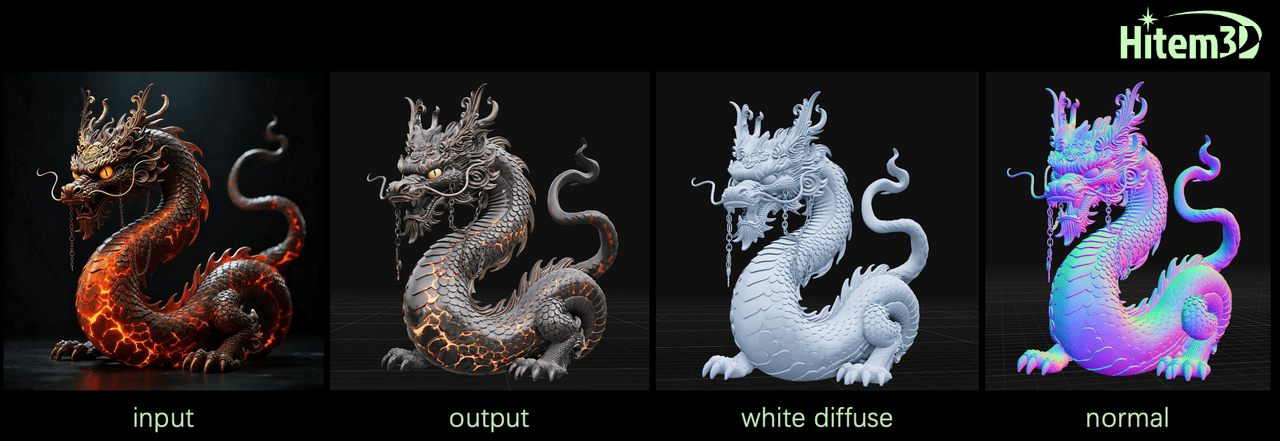

dragon-shaped asset where scales, horns, and whiskers follow the underlying geometry rather than appearing as a flat overlay. With Hitem3D v2.0, the detail holds even as an untextured mesh, with volume and layering that remain intact before finishing, making the asset more directly usable for printing workflows.

What’s New in Hitem3D 2.0? Integrated Texture Generation for Production-Ready Models

Hitem3D 2.0 brings an exciting new feature: integrated texture generation at 1536³ Pro resolution. This isn’t just about creating textures that look good — it’s about creating textures that are part of the model’s geometry from the start. Unlike traditional workflows, Hitem3D 2.0 ensures textures are tied to the scale, geometry, and material logic, resulting in seamless integration between the texture and the 3D model.

Hitem3D’s technical lead explains, “We’re not just trying to make models look flashier. Our goal is to create a consistent production workflow where texture, structure, and logic work in harmony. If the generation isn’t solid, it causes delays and errors in the printing process.”

Why Does This Matter for 3D Printing?

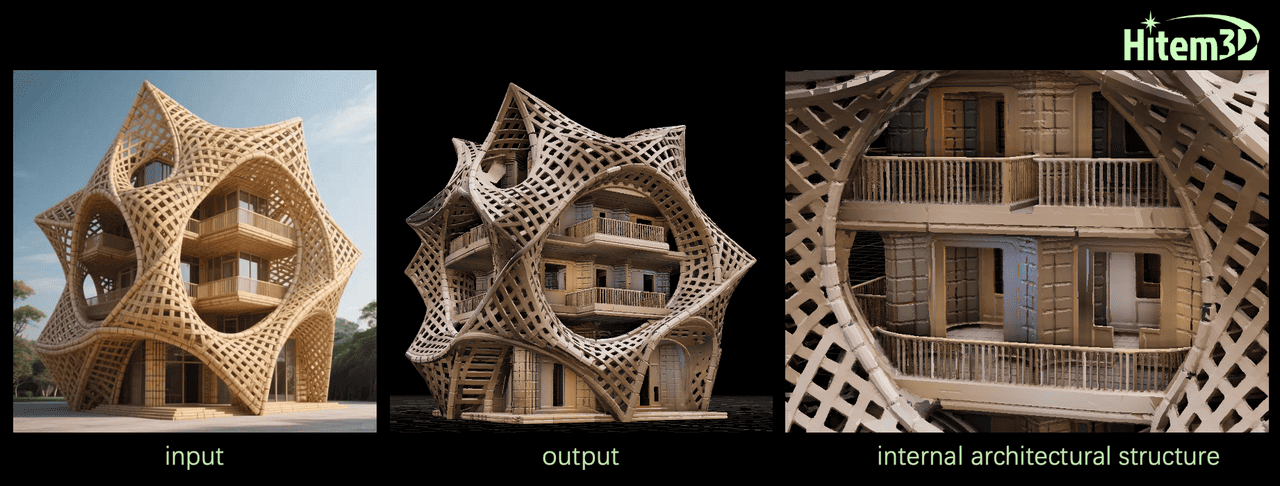

The gap between “looks good” and “production-ready” lies in the finer details — details often overlooked in traditional workflows, like underneath seated figures, hidden interior folds, or the intricate cavities inside architectural models. For professionals working with 3D printing or manufacturing, these missed details can result in costly printing errors.

Hitem3D 2.0 addresses this problem by ensuring that the texture generation happens simultaneously during geometry reconstruction. This leads to a model that’s consistent and complete across both visible and occluded regions, making it much more reliable when sent to print.

Previously, a model might look fine from the front, but printing revealed gaps and inconsistencies. Now, the completion happens during generation, and print directly with fewer fixes.

The Key to Improved 3D Texturing: Material and Lighting Accuracy

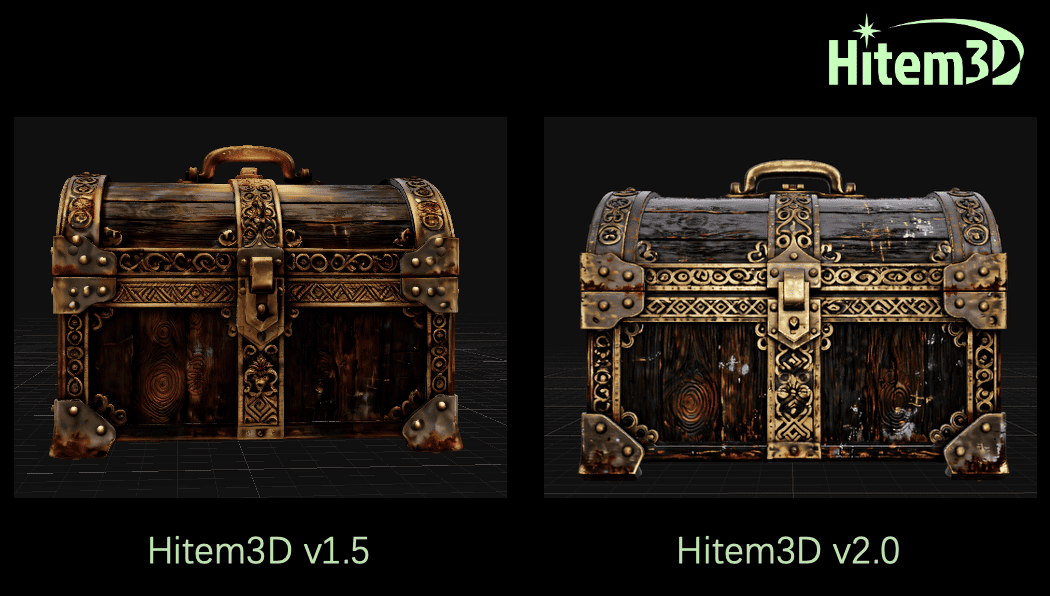

In traditional 3D texturing, lighting often introduces inaccuracies. Highlights and shadows can get baked into textures, creating problems when materials are rendered under PBR (Physically Based Rendering) lighting.

Hitem3D 2.0 resolves this by introducing illumination-aware semantic recognition. This process helps ensure textures are consistently rendered under different lighting conditions and retain material accuracy. The result is a model with a cleaner base that functions seamlessly in downstream workflows.

For example, a wooden crate model generated in Hitem3D 2.0 not only reflects accurate wood grain orientation but also wear patterns on the surfaces, resulting in a more realistic, production-ready model.

Hair-Level Fidelity for Realistic Human Models

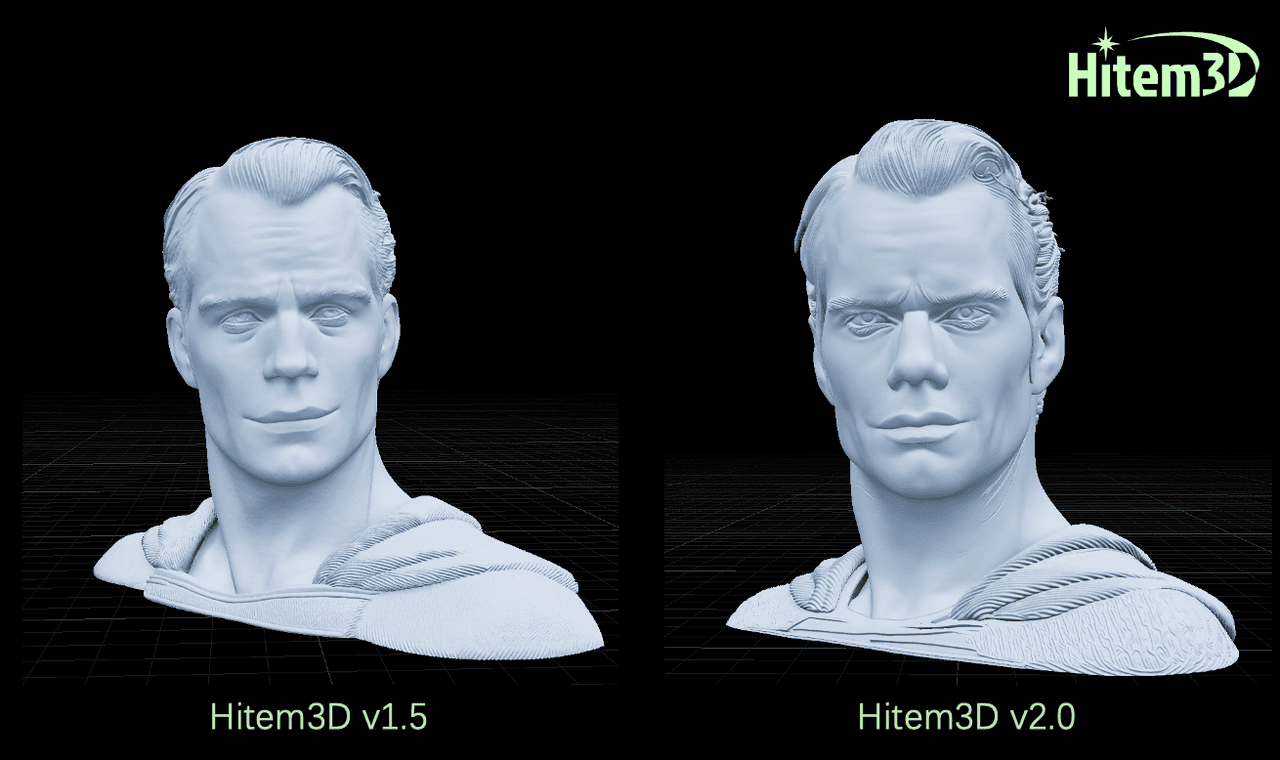

When it comes to 3D modeling humans, hair has always been a challenging element for digital creators. In previous systems, hair models often looked unrealistic, resulting in either clumpy meshes or intersecting geometry.

Hitem3D 2.0 introduces a portrait mode with strand-level fidelity. This feature ensures a more accurate reconstruction of hair flow, brows, and lashes, while maintaining clean transitions between skin and hair. It reduces common issues like interpenetration and manual cleanup time.

A long-time 3D modeling user described the difference in practical terms: clearer curl layers, less chaos, fewer interpenetration issues, and less manual cleanup time on face and hair details.

Hitem3D 2.0 Production Features: Streamlined Workflows and Multi-Material Printing Support

Hitem3D 2.0 is designed as an end-to-end solution for 3D printing and manufacturing workflows:

Semantic 3D model segmentation: Understands parts of the model, not just its surfaces.

Automatic retopology and AI 3D embossing: These features optimize the model for manufacturing.

Multi-material export: Supports up to 4 materials for 3D printing, with future support for 8 or 16 materials.

Additionally, Hitem3D 2.0 supports the USDZ file format, allowing for model revival through the use of reference images and geometry to regenerate textures. This is particularly useful for updating existing models without starting from scratch.

The integration of a Blender add-on further streamlines the workflow, reducing the need for constant switching between programs and enabling a seamless experience for creators.

Why Hitem3D 2.0 is a Game-Changer for 3D Printing and Manufacturing

While many AI 3D tools boast impressive specs, Hitem3D 2.0 focuses on real-world usability and production efficiency. Its integrated texture generation, lighting-aware accuracy, and streamlined production features make it the ideal solution for professionals in 3D printing, manufacturing, and other high-fidelity workflows.

By solving key production issues like structural integrity, material consistency, and reduced rework, Hitem3D 2.0 elevates AI-generated assets from demo models to trustworthy production tools.

The Future of 3D Generation: From Content Acceleration to Production Reliability

The real test for Hitem3D 2.0 will be how it performs in real-world production scenarios. The system is designed to handle complex features, extreme occlusion, and intricate details that are common in actual manufacturing and 3D printing workflows. As AI-generated assets evolve, Hitem3D 2.0 is helping lead the transition from content acceleration to reliable, repeatable production.